Products

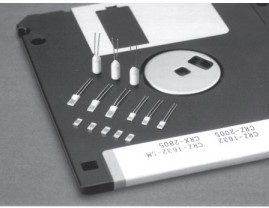

RTD Elements

The epoch-making CRZ Platinum Thin Film RTD elements have been successfully developed by making full use of the state-of-the-art high technologies such as the sputtering technology laying thin films, the ultra fine patterning photolithography and dry etching methods, and the resistance value adjustment by digital trimming for the accurate resistance. Our automated manufacturing process at each stage enables to offer our products being at reasonable prices as well as meeting IEC and JIS Standards.

Special Features:

- In order to save customer's time and make sure to guarantee the quality of our products, we provide all of CRZ elements after inspecting and printing the actual resistance values at

- The elements exclusively made of ceramic and platinum have excellent stability even at high temperature. They are suitable for use between -40 and +500.

- The platinum thin films sputtered on ceramic surfaces are outstandingly resistant to vibration and shock.

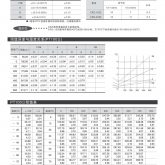

- The latest high technology enables us to produce Pt 500Ω and Pt 1000Ω elements in addition to Pt 100Ω. Those resistance values are not standardized in IEC and JIS but have been recently getting popular in the industrial measurement field.

- The surface of Pt thin films is coated with a ceramic layer in order to withstand high voltage and maintain high insulation resistance.

- We can offer two more classes in addition to class A and class B ; more accurate 1/3 B: industrial class 2B.

- We also provide cylindrical CRX elements improved physical strength as the substitutes of ceramic wire-wound RTD elements.

RTD Elements